FLIR Remote Monitoring for Early Fire Detection in Power Stations

03/04/2025

Empowering Industrial Fire Safety with FLIR

As industrial safety standards rise and the demand for operational continuity grows, early fire detection has become a critical area of investment for facilities like power stations. Traditional methods like smoke detectors and sprinklers are effective but only after ignition. To minimize damage and intervene before a fire breaks out, thermal imaging offers a next-generation solution. This is where FLIR remote monitoring comes into play, empowering operators to detect hot spots long before smoke or flame appears.

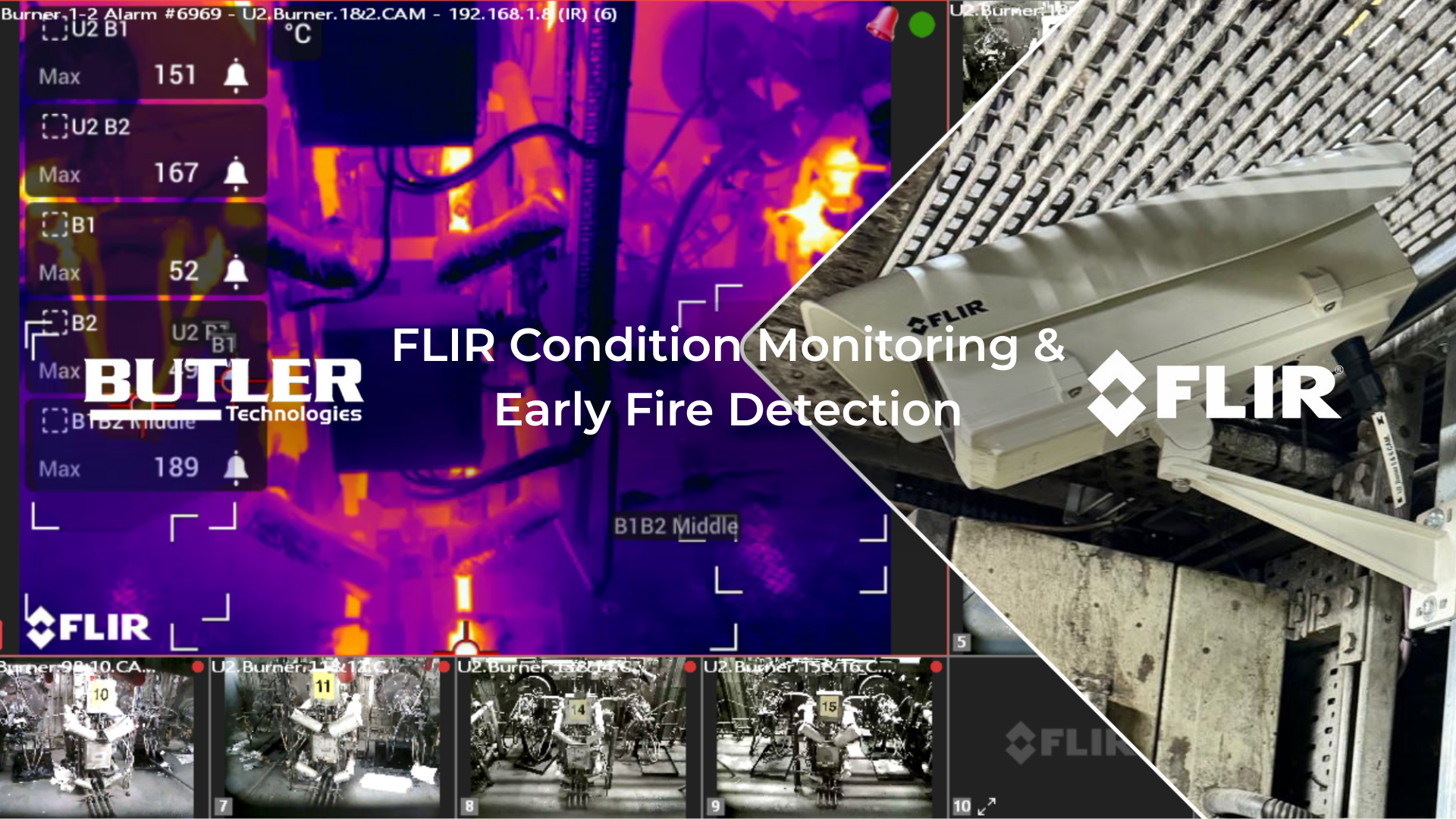

Project Overview: Collaboration Between Teledyne FLIR, Butler Technologies & ESB Moneypoint Station Ireland

This ground breaking project was a collaboration between Teledyne FLIR, Butler Technologies, and ESB Power Stations in Ireland. The mission was clear, to implement a remote monitoring solution for oil burners that would enable early fire detection through threshold-based alerts. With FLIR’s state-of-the-art thermal imaging cameras and Butler Technologies on-ground expertise, the team delivered a solution designed to monitor, detect, and prevent potential fire incidents.

The Challenge: Fire Risk in Oil Burner Systems

Oil burners, central to the operation of power stations, can present serious fire hazards if not continuously monitored. Variations in temperature may indicate burner inefficiencies, impending failure, or the early signs of a thermal event. Without a system in place to track these anomalies in real-time, operators risk catastrophic damage, costly downtime, and safety violations.

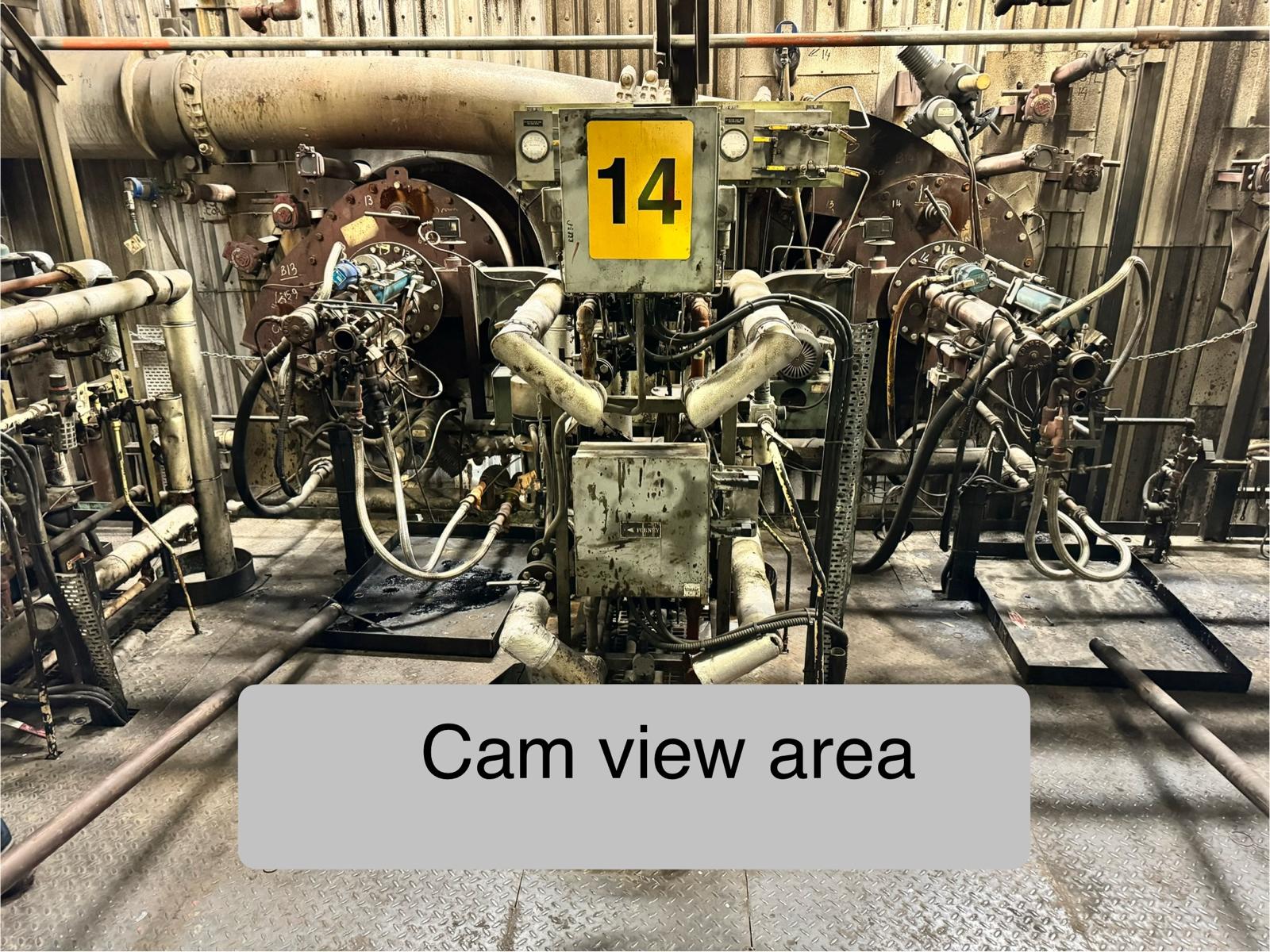

Application at ESB Moneypoint Power Station:

Implementing the FLIR A70 and A500f at ESB power stations can significantly enhance the monitoring of oil burners. Continuous thermal imaging allows for the early detection of irregular temperature patterns, indicating potential issues such as burner inefficiencies or failures. This proactive approach facilitates timely maintenance, reducing unplanned downtime and extending equipment lifespan. Additionally, the integration capabilities of these cameras with existing SCADA systems enable seamless data analysis and real-time decision-making, optimizing operational efficiency and ensuring compliance with safety standards. Incorporating these advanced thermal monitoring systems underscores ESB’s commitment to leveraging cutting-edge technology to maintain reliable and efficient power generation. The Teledyne FLIR A70 and A500f thermal imaging cameras are advanced solutions designed for industrial applications, including monitoring oil burners at power stations like those operated by the ESB in Ireland. These cameras enhance safety, efficiency, and maintenance processes by providing real-time thermal monitoring.

Equipment Deployed: FLIR A70 and A500f

FLIR A70:

The FLIR A70 is an automation thermal camera offering high-resolution thermal imaging with a resolution of 640 × 480 pixels. It features a thermal sensitivity of less than 35 mK, enabling the detection of subtle temperature variations. The camera supports multiple lenses, allowing customization based on specific monitoring requirements. With an accuracy of ±2°C or ±2% of reading, it ensures precise temperature measurements. The A70 is equipped with various measurement tools, including spot meters, boxes, and isotherms, facilitating detailed analysis. Its robust design and compliance with industrial standards make it suitable for challenging environments.

FLIR A500f:

The FLIR A500f is a ruggedized thermal camera designed for harsh environments, featuring an IP67-rated housing that withstands temperatures between -30°C to 50°C. It offers a thermal resolution of 464 × 348 pixels and a temperature detection range from -20°C to 1500°C, accommodating a wide array of industrial applications. The A500f integrates advanced smart sensor capabilities with on-camera analytics and alarm functions, enabling early detection of temperature anomalies. This feature is particularly beneficial for monitoring oil burners, where maintaining optimal operating temperatures is crucial for efficiency and safety.

Installation Process: Survey and Planning by Butler Technologies

A full site survey was conducted by Butler Technologies in partnership with FLIR engineers. The aim was to understand the oil burner configuration, determine risk points, and design a tailored monitoring setup. Based on collected operational values, the cameras were installed with customized lens options and predefined thermal thresholds aligned with site-specific parameters.

Preconfigured Thresholds and Alarm Parameters

The cornerstone of this solution lies in its configurability. Users can define temperature thresholds that match typical and safe operating conditions. For example, if an oil burner typically operates below 150°C, an alert could be configured to trigger at 170°C sustained for 10 seconds. These thresholds are stored on the camera, ensuring quick response times and zero reliance on external processing delays.

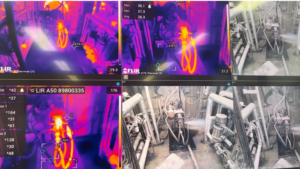

Continuous Monitoring and Predictive Maintenance

Thermal imaging provides a 24/7 watchful eye over oil burners. This continuous data feed enables predictive maintenance identifying wear and potential malfunctions early. With consistent historical temperature trends, technicians can schedule maintenance activities before equipment failures, thus reducing unplanned downtime and associated costs.

Enhancing Operational Efficiency and Safety

Proactive thermal monitoring not only prevents fires but also improves overall operational efficiency. When issues are flagged early, resources can be deployed precisely where and when needed. This level of control results in optimized burner performance, safer environments for personnel, and better compliance with regulatory frameworks.

Real-Time Alerts and Early Fire Detection Benefits

Real-time alerts ensure that anomalies are acted on immediately. These alerts can be sent via email, SMS, or integrated directly into the plant’s VMS or SCADA system. The Project Engineer for Moneypoint has found the system very helpful and allows the team monitoring systems to be one step ahead of a potential breakdown/risk.

Data Analytics and Performance Insights

Beyond safety, FLIR cameras provide analytical value. Heat maps, temperature trend graphs, and recorded events allow plant managers to make data-driven decisions. These insights support everything from performance tuning to regulatory reporting and auditing.

Raising the Bar for Fire Safety in the Energy Sector

This partnership between Teledyne FLIR, Butler Technologies, and ESB Ireland sets a new standard for industrial fire safety. With early fire detection through intelligent thermal monitoring, facilities can shift from reactive fire suppression to proactive fire prevention. It’s a future-proof solution, grounded in data, and tailored to the real-world needs of power generation.

Frequently Asked Questions (FAQs)

- What makes FLIR cameras ideal for power stations? FLIR cameras offer real-time, non-contact temperature monitoring with high accuracy, making them suitable for hazardous and high-value environments like power stations.

- How does thermal imaging prevent fires before they start? By detecting hot spots or abnormal heat signatures before they evolve into ignition, thermal imaging allows for rapid intervention.

- What is the difference between the A70 and A500f? The A70 is optimized for indoor, high-resolution monitoring, while the A500f is ruggedized for harsh, outdoor environments with broader temperature detection ranges.

- Can this solution be applied to other industries? Yes, FLIR thermal cameras are widely used in manufacturing, warehouses, battery storage, recycling plants, and even highway tunnels.

- What kind of maintenance is required for these cameras? Routine visual inspection, occasional lens cleaning, and firmware updates are usually sufficient. FLIR cameras are designed for minimal maintenance in industrial settings.

For more insights and demonstrations check out our News section or get in touch about your business requirements where we can showcase FLIR’s capabilities in real-world scientific applications.

Recent Blogs

18 Jul 2025

|Post by butlertech_admin

Butler Technologies & FLIR Condition Monitoring & Early Fire Detection…

09 Apr 2025

|Post by butlertech_admin

The Critical Role of Battery Monitoring in Power Infrastructure

03 Apr 2025

|Post by butlertech_admin